Plasma for Automobile Manufacturing

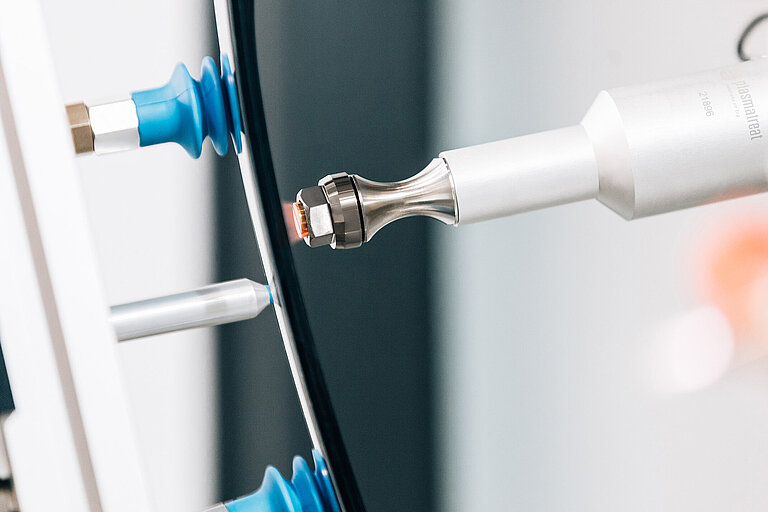

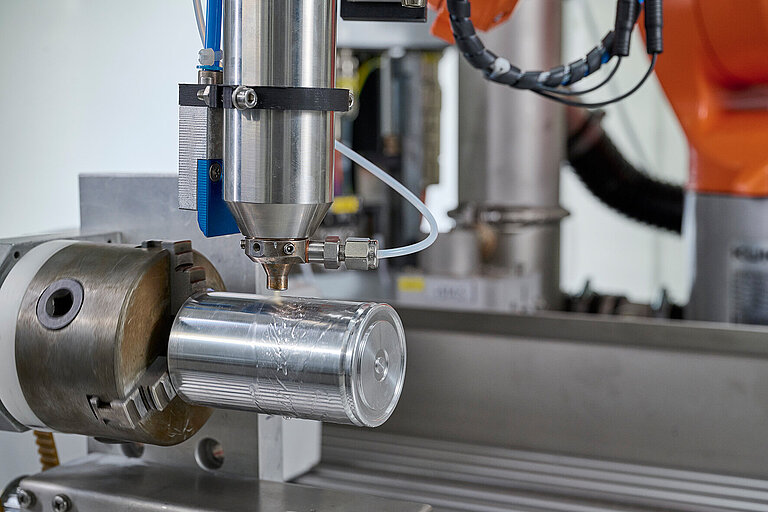

The automotive industry relies on robust, finely tuned processes. These are a basic precondition for achieving consistently high quality. At the same time, durable adhesive bonds and the use of advanced materials are major production parameters when manufacturing parts with complex shapes. Openair-Plasma® treatment meets the tough requirements of the automotive industry like no other pretreatment technology and is therefore firmly established in a variety of production processes at leading manufacturers.

In addition to the atmospheric in-line technology, Plasmatreat's low-pressure processes (Aurora) offer additional opportunities to meet the high quality requirements of the automotive industry.

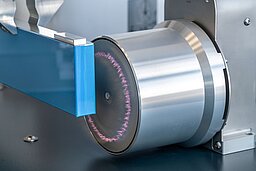

The start of our cooperation with HELLA 30 years ago was a milestone for Plasmatreat: with the first application of Openair-Plasma® for surface treatment prior to the bonding of headlight housings, we laid the foundation for the industrial use of this innovative technology. Today, atmospheric-pressure plasma is an integral part of modern manufacturing processes. In the future, this technology will continue to play a key role in enabling high-performance manufacturing processes and thus the sustainable and efficient production of products.

HELLA part of the FORVIA Group, is a leading global automotive supplier with a focus on lighting technology, electronics, and vehicle access systems.