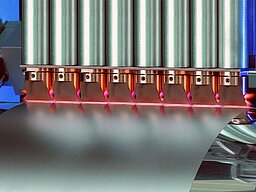

Effective Plasma Film Pretreatment

Openair-Plasma® technology is equally suitable for partial and large-area plasma pretreatment of aluminum foil and plastic films. Thanks to the targeted control of treatment parameters such as temperature, jet offset, jet width and speed, film materials are cleaned, activated or coated efficiently without the use of additives. In contrast to other methods (such as the corona procedure), the mechanical property of the material is maintained with plasma treatment; the surface is not damaged.

Pretreatment of aluminum foils

Openair-Plasma® is a simple and environmentally friendly method of cleaning aluminum surfaces. Composite films are used in particular in the production of beverage and food packaging to keep the packaging gas-tight. Here, the films are lamintated with the aluminium foil (aluminum layer). The material is additionally coated with PE so the aluminum does not come directly in contact with the contents.

The aluminum in the film system is pretreated with Openair-Plasma® to ensure a reliable bond with the PE film. All organic substances, such as rolling oils, are split on the material surface during plasma cleaning and removed. The annealing procedure still widely used in the industry is time- and energy-consuming as compared to Openair-Plasma® treatment. By contrast, with the Openair-Plasma® procedure, the plasma system is integrated inline into the existing overall process. This makes plasma pretreatment especially cost-efficient.

FEATURES &

ADVANTAGES

for the treatment of aluminium foils

- Energy-saving, inexpensive and environmentally friendly

- No change in the foil’s mechanical properties

- Usual treatment width per nozzle = 10 mm (100 nozzles/m)

- Usual treatment width of the foil = 2.20 m

- Two-sided foil treatment possible

- Inline integration of the plasma system before the coil winder (no process interruption)

Pretreatment of plastic films

To be able to print and coat plastic films, the surface tension of the material must first be increased. In addition, coating requires long-term stability of surface activation. In the methods previously available, such as corona treatment or flame treatment, surface tension decreases after a short time.

Pretreatment with the Openair-Plasma® process results in reliable surface activation of the plastic films – activation that displays outstanding long-term stability. Inks and coatings are optimally absorbed.

Openair-Plasma® film systems use special slot jets. They it make possible to reliably treat film with atmospheric-pressure plasma over any width. An additional positive side effect of treating the plastic with Openair-Plasma® is a noticeable anti-static effect.

FEATURES &

ADVANTAGES

for the treatment of plastic films

- Pretreatment with long-term stability due to high surface activation

- Possibility of partial activation

- Additional cleaning effect of additives

- Anti-static effect

- Treatment width per jet = 25 mm

- Single-sided pretreatment

- High processing speeds

Openair-Plasma® makes possible fast and affordable surface modification of large areas of continuous materials, such as textiles, nonwovens, or films.

You want to test our products for your material?

Give it a try: Our experienced application engineers are looking forward working with you to find the best solution for your use case. In our well-equipped laboratories, together we will pre-treat your individual parts with our plasma technology and analyse the results.